The height controller (BCS100) should be calibrated to the excellent level to ensure getting good cutting quality. If you could not get an excellent calibration result, the space between the nozzle and the material might not be precise and stable enough to get a good cutting result. Please follow steps below to figure out and resolve the problems.

When you calibrate the height controller and get a result that is not good enough, please check the DIF value first to make sure if there is a strong electromagnetic interference in the system.

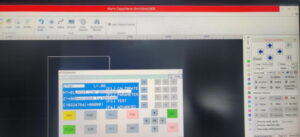

Press 5 on the main menu and enter the capacitance monitoring interface, then check the DIF value, shown as below.

If the DIF value is greater than 30, then there is a strong electromagnetic interference in the system, and please contact us for further support. Otherwise, please check all the parts on the sensor (including the nozzle, the ceramic ring, the sensor body, and the wire). Refer to CypCut Alarm: Capacitance diminished for more information.