Homing progress is critically important for laser machines to set up a correct coordinate system of working area for later operations, like jogging, cutting, engraving, everything related to laser head moving.

Table of Contents

Recap Correct Homing Progress

Before diving into troubleshooting sections, it’s better to have a brief look of correct homing progress, which will help you understand what happens to your machine.

After power on, laser head should go fast towards to home position of X and Y axis at the same time. After limit sensor of, for example, X axis is triggered, laser head would slow down and stop going towards right (left on some machines), come back left until laser head leaving effective section of sensor. Then, laser head would go towards right again, but much more slowly, to trigger limit sensor, and come back left again to confirm home position accurately. Same progress would be happened on the other axis, and the homing progress would be finished properly with (0, 0) of the coordinate system set up.

Laser head would go to programmed origin after homing progress if there’s one set up.

Troubleshooting

Improper homing progress will set laser machines in a nonoperational state, or cause a lot of problems on later operations, even if you cancel the progress manually and choose to continue working.

Please refer to sections below according to the specific situation of your laser machine.

Laser head does not stop on right/back side, and cracks on frame parts.

Case Confirmation

In this case, laser head goes fast towards to home position normally, but does not stop even when it’s very closed to limit sensor(s), and cracks on right or back side frame parts finally.Cause

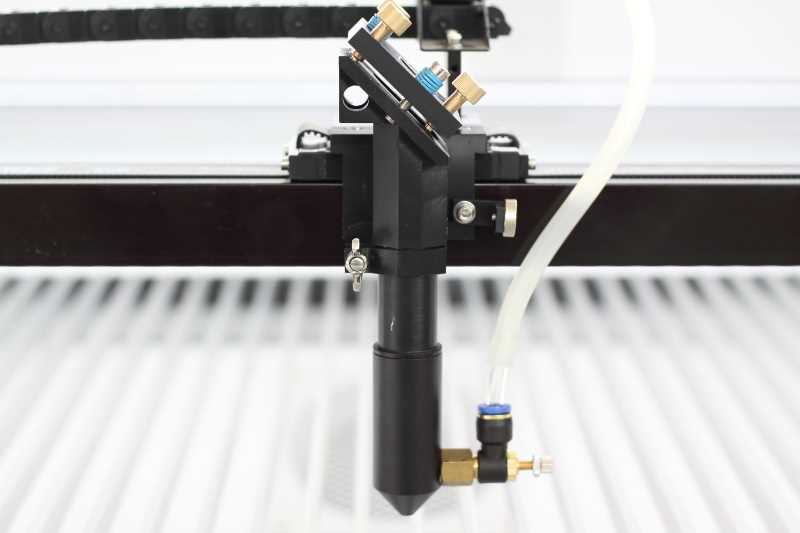

- Air assist adjustment knob is towards right, not to the front. Sometimes, it will crack on right side frame parts before laser head coming into effective section of limit sensor of X axis.

- Limit sensor of X axis function abnormally.

- Limit sensor of Y axis function abnormally.

Solution

- Rotate laser pen, let air assist adjustment knob face front.

- Replace limit sensor of X axis. If that still doesn’t work, check wire connection between sensor and control card. Replace wire if it’s broken.

- Replace limit sensor of Y axis. If that still doesn’t work, check wire connection between sensor and control card. Replace wire if it’s broken.

Diagnosing Tips

Laser head moves very slowly away from home position after new control card installed.

Case Confirmation

In this case, laser head moves very slowly away from home position immediately after power on. The progress will be stopped automatically after a long time (several times longer than normal homing progress), due to a self protection mechanism. Instead of having a coordinate system correctly being set up, the laser machine will get current position of laser head setting up to a pair of fixed value, usually (10000, 10000) (you can check that out on control panel).

Cause

Control card is not set up correctly.

Solution

Contact us, get correct profile of your laser machine, program control card via EagleWorks or RDWorks according to card type.

Refer to this Technical Reference for more information.