FiberMark F2

LASER MARKING MACHINE

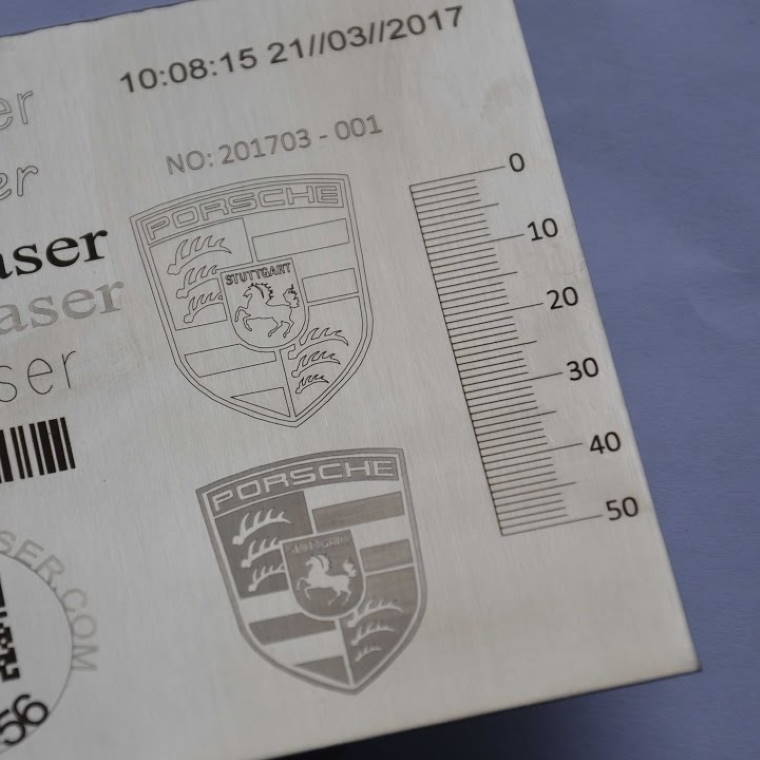

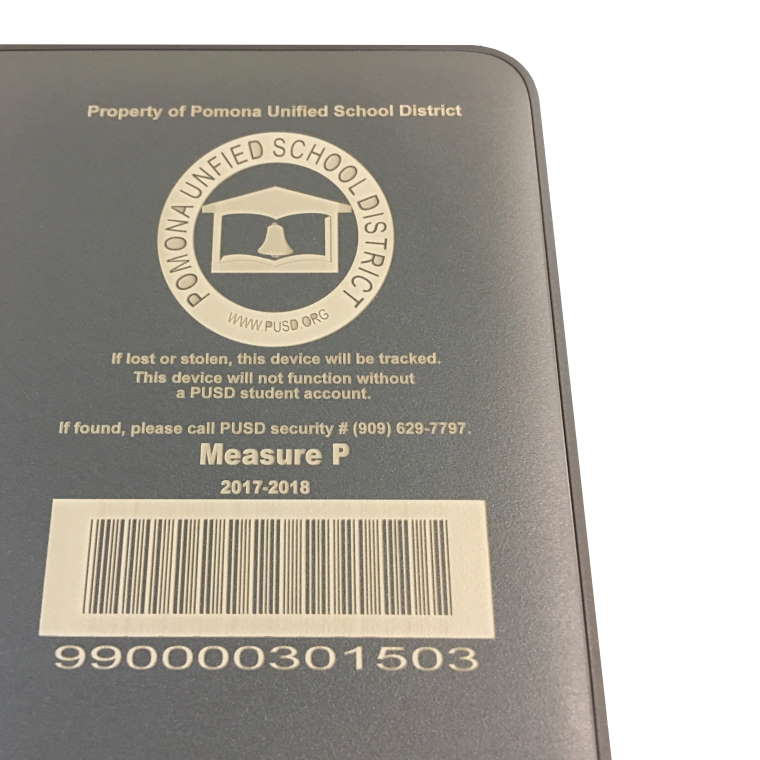

Our smallest and most popular fiber laser marking machine, the F2 offers a low-cost, high-quality solution for businesses transitioning from more traditional means of engraving, etching, and surface marking all types of metal, stone, and tile. Commonly used by custom awards and serialized part manufacturers alike, the open working area design and lightning-quick galvo system offers a cost-effective and highly efficient solution to all your etching and engraving needs.

Start at

$6,999

Technical Specifications

Working Area* |

Standard 4.3″ x 4.3″ (110 x 110mm), optional 7″ x 7″ (175 x 175mm). |

Working Table |

Aluminum plate table with an array of threaded holes for aligning or fixing work pieces. |

Laser Source |

Fiber Laser |

Laser Power* |

30W / 50W |

Software |

EzCAD CAD/CAM, compatible with Windows 7/8/10. |

Machine/PC Connection |

No computer included. Connected by USB. |

Control Interface |

Direct control in software. |

Motion System |

Fast galvo motion system. |

Accessories* |

Optional rotary. |

Electrical Requirement |

220V/50Hz, single phase, up to 0.3kW. |

Size |

34″ x 21″ x 28″ (860 x 530 x 710mm) |

Net Weight |

110lb (50Kg) |

Note: All specifications marked with * depend on configurations of the laser machine.

FEATURES

Our FiberMark F2 laser marking machines are designed with user convenience and flexibility in mind. Hardware and software are integrated in a complete, ready-to-use package with many features that enhance usability and profitability.

Note: All features marked with * depend on configurations of the laser machine.

This compact laser marking machine has a very small footprint, designed for laying on a desktop with a computer beside.

The galvo head of the laser machine features manual up and down movement, to accommodate material with different thickness, abnormally shaped work pieces or a rotary unit for use with pipe and rod stock.

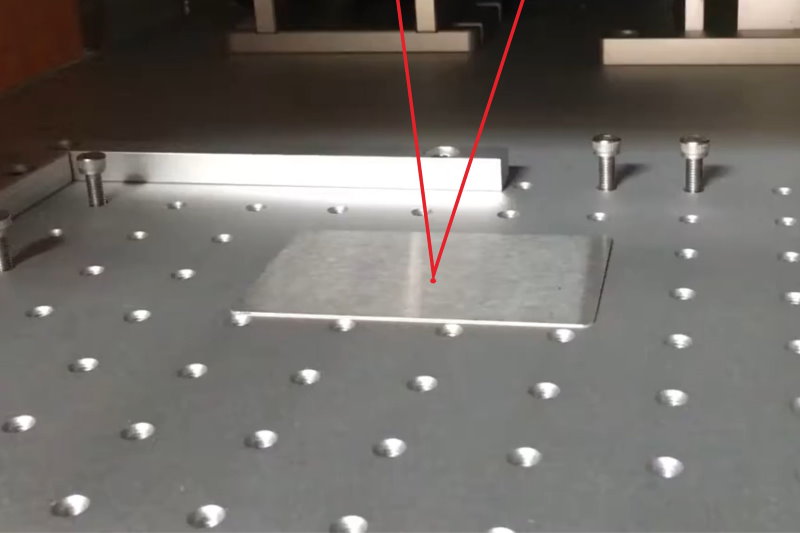

Two red dot indicators integrated and pre-adjusted on the galvo head, helping you get the right focus quickly and precisely, saving you a lot of time when working on work pieces with different thicknesses.

You can adjust marking area and resolution by changing lenses. The lens with small marking area, e.g. 3″ x 3″ (75 x 75mm), is ideal for detail marking, such as marking on jewelry. While processing a big design, you’ve to use the lens with large marking area.

With the tracing function, the red dot laser, which is coaxial with the fiber laser, allows you to have a visual reference for the area where the laser will fire. It can even trace the contour of the design with the specific option in the software activated.

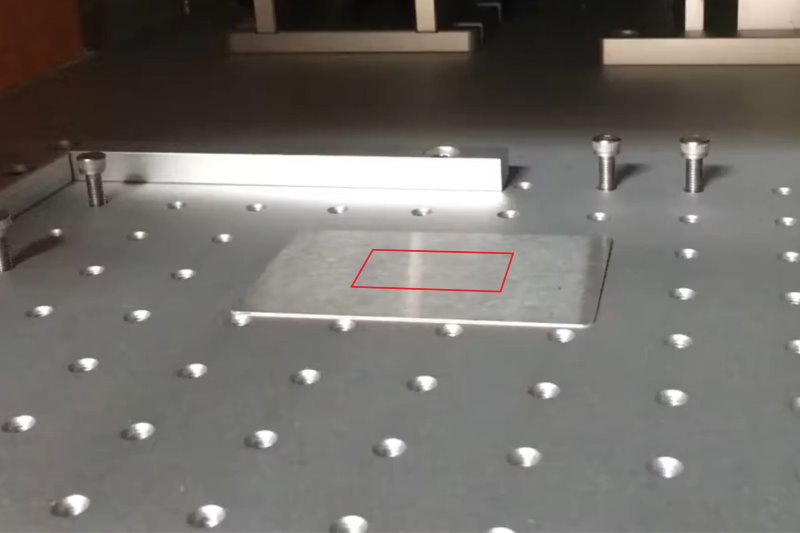

There is an array of threaded holes on the working table, which can be used to fix the edge guiding bars, align or fix work pieces. Or you can make your own tooling templates for a group of, or abnormally shaped work pieces with the aid of these threaded holes.

Thanks to its height adjustable galvo head, the laser machine can be equipped with an rotary unit for marking pipe or rod around its circumference.

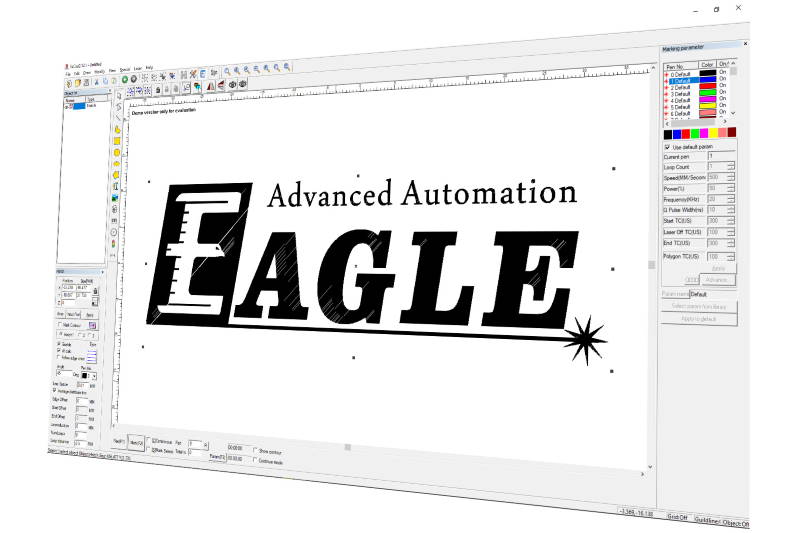

We supply your machine with EzCAD, a complete software solution for creating, editing, optimizing, and processing patterns for laser marking. You can import a design from your favorite CAD or illustration program, or create an original design with the EzCAD software. Then you can adjust the marking order, specify the layout within the processing area of the machine, and finally control the machine directly from inside the software.

The laser machine is very easy to setup, just take it out from the crate, connect it all together, and you are ready to run your first job!

With galvo system from the world’s leading suppliers, the laser machine can do marking extremely fast with high precision.

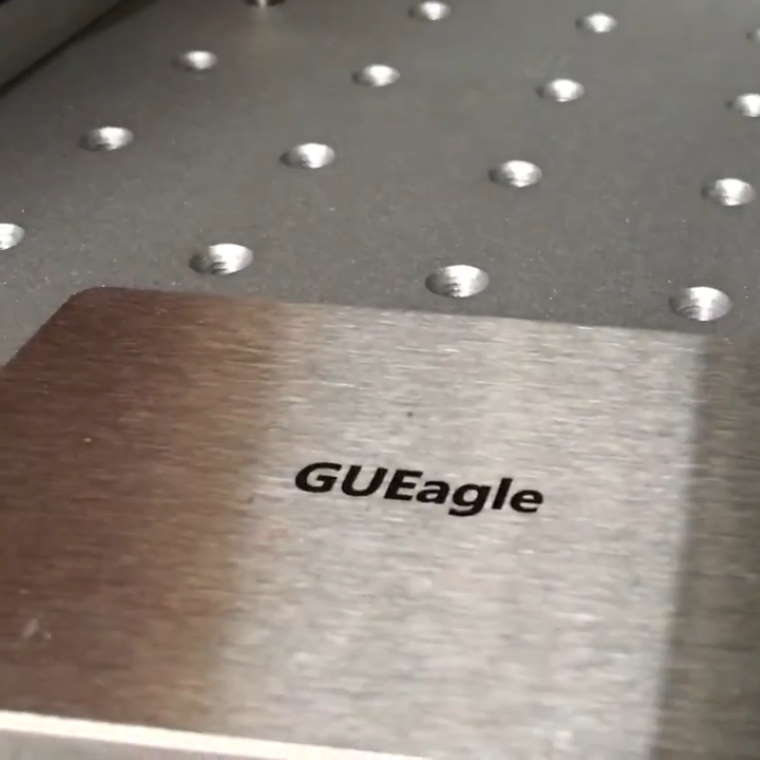

The laser machines are equipped with top-quality, American-made optics, to provide a consistent laser beam across the entire marking area. This allows the laser machines to achieve industry-leading marking quality.

The laser machine is equipped with a 30W or 50W fiber laser, with great cost performance ratio, high productivity and marking consistency. It will allow you to get more done in less time with unmatched marking quality.

The laser machines are designed, engineered, and built with safety and reliability in mind.

We use electronic parts from the world’s leading suppliers and build the system to international standards.

YOU ARE IN GOOD HANDS

WITH OUR U.S. LOCAL TECH SUPPORT TEAM

TO PROVIDE ON-SITE SERVICE

APPLICATIONS

Our FiberMark F2 laser marking machines can be used for marking of metal, plastics and more.

Stainless Steel

Stainless Steel

Plastics

Plastics

DOWNLOADS

Manuals, books, documents and software which help you get to know and use the laser.

EzCad CAD/CAM

The CAD/CAM software comes with your machine for creating a design, laying out, setting technology and laser marking.

YOU MAY ALSO LIKE

FiberMark F1

LASER MARKING MACHINE

Fully enclosed, all-in-one galvo laser marking machine including laser source, computer, monitor, mouse + keyboard, rotary unit, EzCad CAD/CAM software, and your choice of lens.

| Working Area | Up to 8" x 8" (200 x 200mm) |

| Laser Source | Fiber laser / MOPA |

| Laser Power | Up to 100W |

| Operating Mode | Marking |

EF-HYBRID

MULTI-FUNCTION

LASER WELDING MACHINE

With 1,500 watts of available power, the EF-Hybrid fiber laser welding machine allows you to weld, clean, and cut all kinds of metal with ease.

| Working Area | Handheld / Open area |

| Laser Source | Fiber laser |

| Laser Power | 1.5kW |

| Operating Mode | Welding / Cleaning / Cutting |

EV-30

INDUSTRIAL

LASER CUTTING MACHINE

Economical, high-speed, high-precision solution for sheet metal fabrication and production; available in 3kW and 6kW variants.

| Working Area | 5' x 10' (1500 x 3000mm) |

| Laser Source | Fiber laser |

| Laser Power | Up to 6kW |

| Operating Mode | Cutting |