X-1309

GENERAL PURPOSE

LASER CUTTING MACHINE

One of our most popular machines, the X-1309 is our largest general purpose CO2 laser machine with a variable-height working area. Fitted standard with a 150-watt laser tube (available in up to 300-watts), this machine has proven to be a vital tool for businesses in a wide variety of industries ranging from textile and garment manufacturing, to sign making and prototyping. With a metal blade or honeycomb bed (51″ x 35″) and integrated fume extraction system, this machine is ideal for the workshop looking for a durable, easy to use solution for high-speed, precision production. The variable height working area (Z-axis) on this, and all our CO2 laser machines allows you to work on material over 8″ tall.

Start at

$12,000

Technical Specifications

Working Area |

51″ x 35″ (1300 x 900mm) Can fit uncut sheets or long work pieces (along Y direction) with full pass-through capability. |

Max. Workpiece Height |

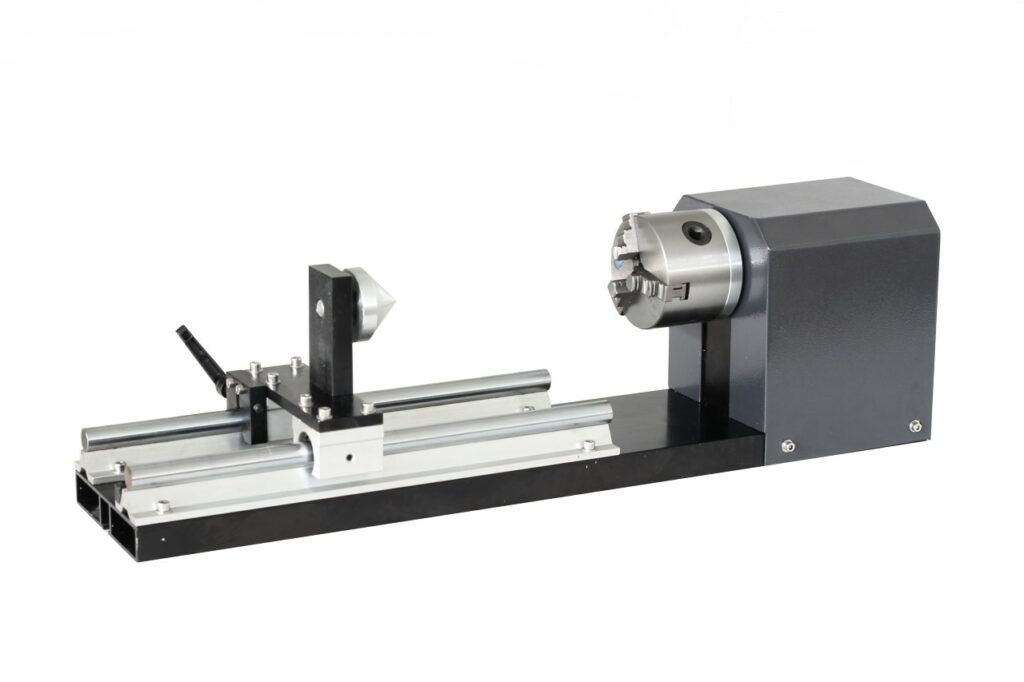

8″ (200mm) by motorized Z axis, can accommodate abnormally shaped work pieces or an optional rotary unit for use with pipe and rod stock. |

Working Table* |

An aluminum strip table for hard and flammable materials (acrylic, cardboard, wood, etc.), and a full-support honeycomb table suitable for soft material processing (paper and textiles). |

Laser Source |

CO2 Sealed Glass Laser Tube |

Laser Power* |

100W / 130W / 150W |

Laser Configuration* |

Single / Dual laser(s) |

Focus Lens* |

Standard 2.5″ (63.5mm), optional 4″ (101.6mm), or 2″ (50.8mm, can be equipped with a special laser pen). |

Software |

EagleWorks CAD/CAM and EaglePrint print driver, compatible with Windows 7/8/10. 100% support LightBurn software. |

Machine/PC Connection |

USB / FLASH / LAN |

Operating Mode |

Cutting / Engraving / Combined |

Control Interface |

True Color TFT LCD panel with function buttons. |

Memory Capacity |

Multiple job storage up to 128M. |

Resolution |

Up to 4064 DPI. |

Motion System* |

Transmission with belt on advanced balanced bearing rails. Driven by stepper / servo motors. |

Accessories |

Air assist pump, industrial chiller and exhaust blower included. |

Electrical Requirement* |

220V/50Hz, single phase, up to 2.5kW~4.5kW depends on configurations. |

Size |

75″ x 67″ x 43″ (1900 x 1700 x 1100mm) |

Net Weight |

880lb (400Kg) |

Note: All specifications marked with * depend on configurations of the laser machine.

Material Compatibility

Engrave | Cut | |

|---|---|---|

Acrylic | ● | ● |

Paper | ● | ● |

Wood | ● | ● |

Textiles | ● | ● |

Leather | ● | ● |

Laminates | ● | ● |

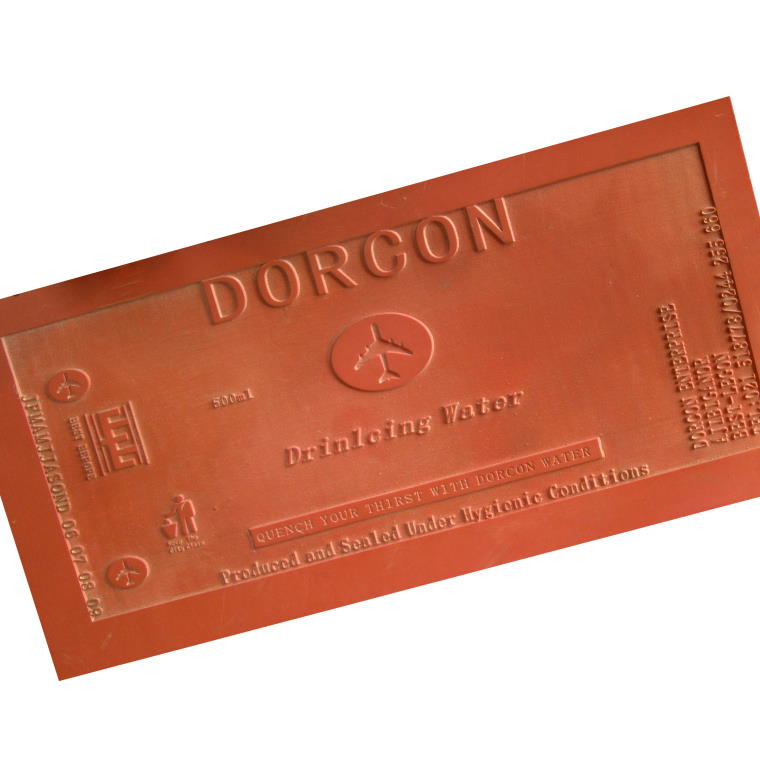

Rubber | ● | ● |

Stone | ● | – |

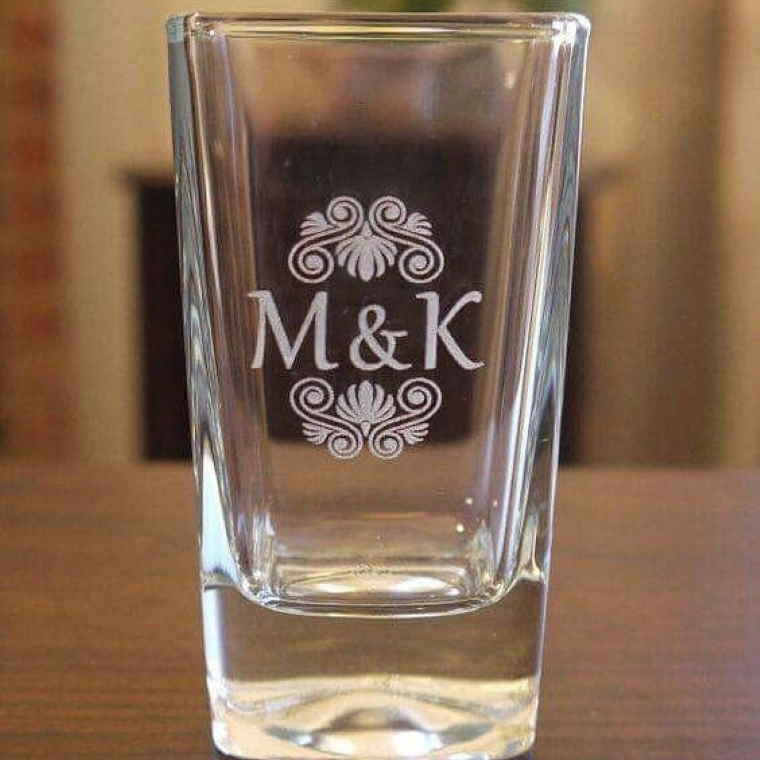

Glass | ● | – |

Coated Metals | ● | – |

FEATURES

Our general purpose laser cutting machines are designed with user convenience and flexibility in mind. Hardware and software are integrated in a complete, ready-to-use package with many features that enhance usability and profitability.

Note: All features marked with * depend on configurations of the laser machine.

The 51” (1300mm) working width comfortably accommodates standard 48” (1200mm) wide sheet material.

The working table features powered up and down movement, to accommodate abnormally shaped work pieces or an optional rotary unit for use with pipe and rod stock.

Openable front door and back panel give the laser machine full pass-through capability, allowing you to work with uncut sheets, process long work pieces, or use continuous roll material.

We provide both an aluminum strip table for hard and flammable materials (acrylic, cardboard, wood, etc), and a full-support honeycomb table suitable for soft material processing (paper and textiles). Both minimize laser reflection and ensure a clean cut edge.

Thanks to its height adjustable working table, the laser machine can be equipped with an optional rotary unit for cutting and engraving pipe or rod around its circumference.

After cutting, parts small enough to fit through the honeycomb or strip table will drop down to a deep collecting bay, avoiding damage by the laser during subsequent cutting operations. They can be retrieved simply by opening the drawer after cutting is complete.

The laser machine can be equipped with single or dual laser cutting/engraving heads. Dual heads allow two copies of the same pattern to be cut simultaneously on a single sheet of material. The spacing between the heads can be adjusted at any time (based on the repeat width of the pattern) using just a screwdriver.

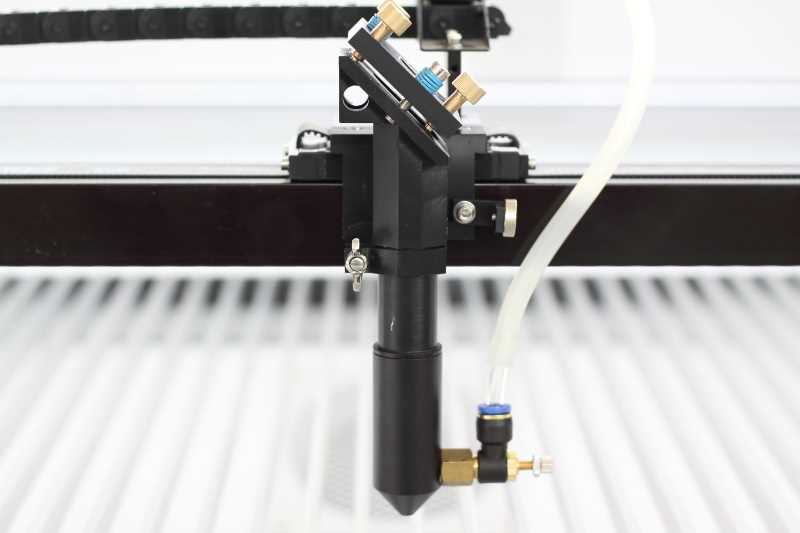

We offer two focal lengths of lens for use in our standard laser heads. The 2.5” (63.5mm) lens is ideal for general purpose laser cutting and engraving, while the 4” (101.6mm) lens is best for cutting material over 20mm thick. The standard laser head has two lens mounting positions, so the spacing from the bottom of the nozzle to the material is the same with both lenses.

The laser head includes an adjustable air assist assembly. A constant stream of compressed air protects the lens from dust or cutting vapor, and sweeps the cutting surface, reducing the possibility of flaming, scorching, or charring when cutting materials such as acrylic or wood.

The laser machine is equipped with a high performance control system with a user-friendly interactive panel.

The high-resolution, true color TFT LCD panel lets you preview machine status and job details before processing. You can adjust parameters for different materials, or even run a processing simulation on the panel.

While processing, you will see real-time status information on the panel, and you can adjust parameters on the fly according to the results you are seeing.

If there is a power failure or the emergency stop is hit, all configuration and job status information is automatically saved. After the problem is cleared, cutting or engraving can resume exactly where it left off, preventing material wastage.

Embedded flash storage in the controller lets you transfer jobs to the machine by USB, Ethernet or flash drive and finish processing offline without relying on a connection to your PC.

We supply your machine with EagleWorks, a complete software solution for creating, editing, optimizing, and processing patterns for laser cutting and engraving. You can import a design from your favorite CAD or illustration program, or create an original design with the EagleWorks software. Then you can adjust the cutting/engraving order, specify the layout within the processing area of the machine, run a processing simulation, and finally control the machine directly from inside the software running on your PC.

As an alternative to using the EagleWorks software, you can run the machine directly from within your favorite CAD or illustration program using our print driver. This software makes the laser machine look to your computer as if it were just another printer, to which you can “print” from any application, including AutoCAD, Adobe Illustrator, Photoshop, CorelDRAW, etc.

When controlling the machine through the print driver, you use color and line thickness settings in the drawing to control the laser power (cutting vs. engraving) and the order of cutting. This allows you to easily combine cutting and engraving in a single job, for faster processing and more precise control of the laser.

Half-toned photographs and other images can be laser-engraved by “printing” directly from inside your favorite image editing software. When using software that supports both raster images and vector drawing (e.g. Adobe Illustrator, CorelDraw, etc) a simple one-step Print command can do both cutting and engraving simultaneously.

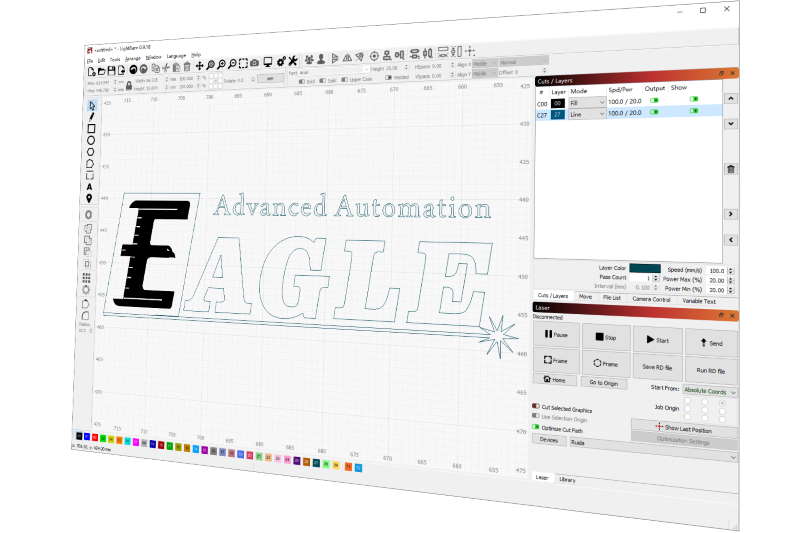

LightBurn is layout, editing, and control software for your laser cutter. With LightBurn you can:

- Import artwork in a variety of common vector graphic and image formats (including AI, PDF, SVG, DXF, PLT, PNG, JPG, GIF, BMP)

- Arrange, edit, and even create new vector shapes within the editor, with powerful features like offsetting, boolean operations, welding, and node editing

- Apply settings like power, speed, number of passes, cut order, brightness & contrast, dithering mode, and much more

- Send the result directly to your laser cutter

LightBurn is a native application written for Windows, Mac OS, and Linux, and talks directly to the laser, without the use of additional software.

We provide a complete, ready-to-use package with all the necessary parts to get your machine up and running.

A high quality industrial water chiller circulates cooling water through the laser tube, ensuring continuous and stable laser output power.

A powerful exhaust blower maintains negative pressure within the entire machine enclosure, ensuring efficient extraction of dust and fumes from both above and below the work piece.

We supply all the ductwork needed to vent the machine to the outside.

Just connect it all together and you are ready to run your first job!

The linear bearings and slide rails used in the laser machines are thicker and stronger than in competitive models, ensuring long-term stability of the laser path. That means less downtime, more productivity, and more profit.

The laser machine can be equipped with single or dual 100W, 130W, or 150W glass CO2 laser tubes, all with great cost performance ratios. (Dual laser systems include two cutting heads, allowing you to cut or engrave twice as much material in the same amount of time.)

If engraving is a large part of your work load, you can increase productivity and engraving consistency with our 50W or 100W RF metal tube laser. It will allow you to get more done in less time with unmatched engraving quality.

The laser machines are equipped with top-quality, American-made optics, to provide a consistent laser beam across the entire working area. This allows the laser machines to achieve industry-leading cutting and engraving quality.

The laser beam is carried from the laser tube to the laser head by a series of mirrors, whose alignment is crucial for good performance. Our mirror mounting and adjusting system is the best in the world, designed for stability and ease of use. In most cases the machine will not require any alignment after installation, but if it goes out of calibration for any reason, three adjustment screws per mirror allow you to achieve perfect alignment with minimal frustration.

The laser machines are designed, engineered, and built with safety and reliability in mind.

We use electronic parts from the world’s leading suppliers and build the system to international standards. Sensors throughout the machine detect unsafe conditions, including door open, laser tube box open, laser cooling water pressure or flow failure, and so on. The machine will stop automatically if any unsafe condition is detected. There is also a panic button on the front panel which will immediately and completely shut down all power to the machine.

YOU ARE IN GOOD HANDS

WITH OUR U.S. LOCAL TECH SUPPORT TEAM

TO PROVIDE ON-SITE SERVICE

APPLICATIONS

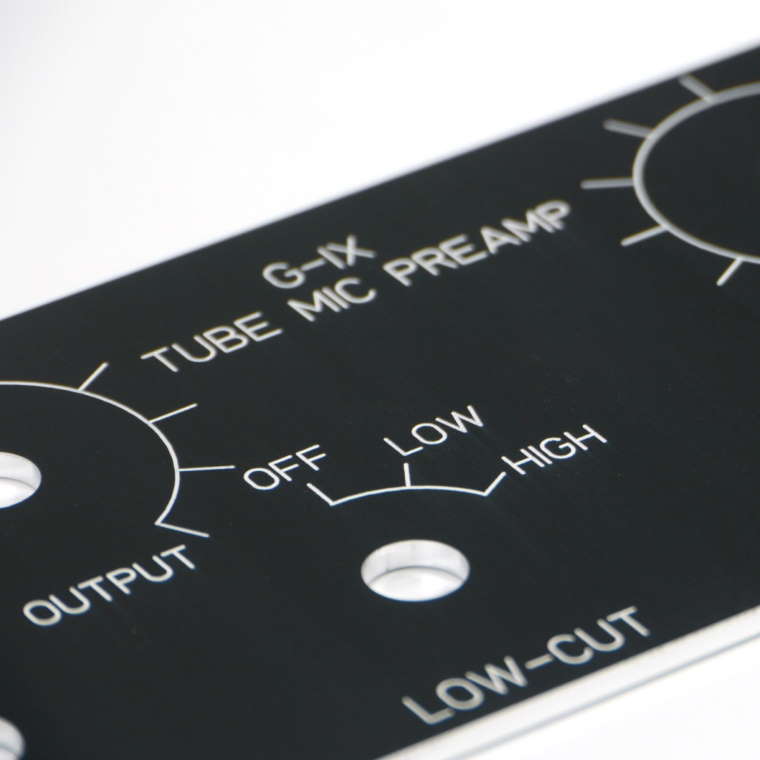

Our general purpose laser cutting machines can be used for cutting and engraving of acrylics, cardboard, wood, textiles, two-color sign laminate, stone, and much more.

Acrylic

Paper & Cardboard

Wood

Textiles & Leather

Sign Laminate

Rubber Stamp

Stone

Glass

USE CASES

See how our customers succeed and grow their business with our lasers.

The STEAM Maker Workshop

Gift Maker for Disney

DOWNLOADS

EagleWorks CAD/CAM

Bundled CAD/CAM software coming with the customized EAGLECAM control system. A complete software solution for creating, editing, optimizing, and processing patterns for laser cutting and engraving.

EaglePrint CAM

A print driver software which help you use the laser as a printer. You can make a design in your favorite drawing software, e.g. CorelDRAW, Adobe Illustrator, AutoCAD, Adobe Photoshop, even Microsoft Word, and then "print" to the laser and get the job done.

LightBurn Software

The laser machine is 100% compatible with the LightBurn software. LightBurn is layout, editing, and control software for the laser, a native application written for Windows, Mac OS, and Linux, and talks directly to the laser, without the use of additional software.

Laser System Manual

A complete reference book for the laser machine.

YOU MAY ALSO LIKE

H-1610

LASER CUTTING MACHINE

Closed-cabin CO2 laser cutting machine.

| Working Area | 63" x 39" (1600 x 1000mm) |

| Laser Source | CO2 laser tube |

| Laser Power | Up to 150W |

| Operating Mode | Cutting / Engraving / Combined |

H-1325

LARGE FORMAT

LASER CUTTING MACHINE

Our largest open table flatbed CO2 laser (4ft x 8ft) which comes equipped with integrated exhaust system, high speed belt-driven gantry, and camera system for high-speed, automated cutting and engraving of acrylic, wood, cardboard, and more.

| Working Area | 4' x 8' (1300 x 2500mm) |

| Laser Source | CO2 laser tube |

| Laser Power | Up to 300W |

| Operating Mode | Cutting / Engraving / Combined |

X-7050

DESKTOP

LASER ENGRAVING MACHINE

Entry-level CO2 laser machine designed for extremely high-resolution engraving and fast cutting of acrylic, wood, cardboard, and much more.

| Working Area | 27.5" x 19.7" (700 x 500mm) |

| Laser Source | Metal CO2 laser tube |

| Laser Power | 40W |

| Operating Mode | Engraving / Cutting / Combined |