100-150W CO2 LASER TUBE

$680.00 – $1,500.00

How much laser power is best for me?

130W CO2 laser is the most cost effective choice for cutting (can cut acrylic up to 1" in thickness). 150W CO2 laser is best suitable for cutting ultra-thick materials (can cut acrylic up to 1-1/4" in thickness). While 100W CO2 laser is better choice for precise engraving and cutting a little thin material (can cut acrylic up to 3/4" in thickness).

Metal Heads

The metal heads on both ends of the CO2 laser tubes ensure stable structure, laser beam quality and output power, and help achieving better heat control while operating.

High Quality Optics

The CO2 laser tubes are equipped with top-quality, American-made optics, to achieve stable output power and good laser beam mode.

Advanced Coating Technology

The advanced coating technology featured in the production process effectively enhances the stability and life time of the CO2 laser tubes.

High Voltage Insulator

There is a high voltage insulator covering the end of the CO2 laser tube, to protect operators and laser machine from high voltage damages.

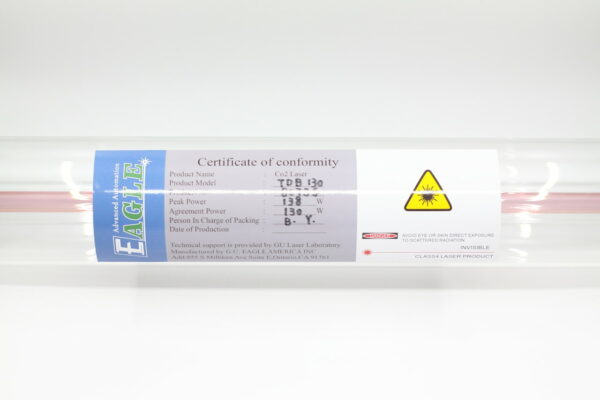

Tracing Label

There is a tracing label on every single CO2 laser tube, with the serial number and technical specifications on it. You can get in touch with us easily with the label.

Enjoy our fist-class service!

Enjoy our fist-class service!

Safety and Reliability

The CO2 laser tubes are designed, engineered, and built with safety and reliability in mind.

We use parts from the world’s leading suppliers and build the laser tubes to international standards.

We use parts from the world’s leading suppliers and build the laser tubes to international standards.

Packing

The CO2 laser tube are packed with foam fixing rings and foam pads on both ends of it, inside a strong cardboard case. And we provide a bigger case which can hold four packs for users who buy four or more tubes at once.

Technical Specifications | |||

|---|---|---|---|

EA-100 | EA-130 | EA-150 | |

Output Power (Rated/Max.) | 100W/135W | 130W/170W | 150W/185W |

Beam Quality (m²) | ≤1.1 | ||

Beam Waist (mm) | 6.2 | 6.4 | 6.6 |

Beam Divergence (mard full angle) | 3.1 | ||

Maximum Strike Voltage (kV) | 40 | ||

Rated Operating Current/Absolute Max.(mA) | 20/35 | ||

Optimum Current Used (mA)/(W) | 25/120 | 25/150 | 30/180 |

Diameter | 3.15″ (80mm) | ||

Length | 58.27″ (1480mm) | 66.93″ (1700mm) | 66.93″ (1700mm) |

EA-100 Technical Specifications |

|

|---|---|

Output Power (Rated/Max.) |

100W/135W |

Beam Quality (m²) |

≤1.1 |

Beam Waist (mm) |

6.2 |

Beam Divergence (mard full angle) |

3.1 |

Maximum Strike Voltage (kV) |

40 |

Rated Operating Current/Absolute Max.(mA) |

20/35 |

Optimum Current Used (mA)/(W) |

25/120 |

Diameter |

3.15″ (80mm) |

Length |

58.27″ (1480mm) |

EA-130 Technical Specifications |

|

|---|---|

Output Power (Rated/Max.) |

130W/170W |

Beam Quality (m²) |

≤1.1 |

Beam Waist (mm) |

6.4 |

Beam Divergence (mard full angle) |

3.1 |

Maximum Strike Voltage (kV) |

40 |

Rated Operating Current/Absolute Max.(mA) |

20/35 |

Optimum Current Used (mA)/(W) |

25/150 |

Diameter |

3.15″ (80mm) |

Length |

66.93″ (1700mm) |

EA-150 Technical Specifications |

|

|---|---|

Output Power (Rated/Max.) |

150W/185W |

Beam Quality (m²) |

≤1.1 |

Beam Waist (mm) |

6.6 |

Beam Divergence (mard full angle) |

3.1 |

Maximum Strike Voltage (kV) |

40 |

Rated Operating Current/Absolute Max.(mA) |

20/35 |

Optimum Current Used (mA)/(W) |

30/180 |

Diameter |

3.15″ (80mm) |

Length |

72.84″ (1850mm) |

Material Compatibility | ||

|---|---|---|

Engrave |

Cut | |

Acrylic |

● | ● |

Paper |

● | ● |

Wood |

● | ● |

Textiles |

● | ● |

Leather |

● | ● |

Laminates |

● | ● |

Rubber |

● | ● |

Stone |

● | – |

Glass |

● | – |

Coated Metals |

● | – |

Be the first to review “100-150W CO2 LASER TUBE”Cancel Reply

You may also like…

-

100-150W CO2 LASER POWER SUPPLY

$240.00 – $360.00 -

CO2 LASER CHILLER

$585.00

Related products

-

∅19mm CO2 LASER LENS

$150.00 -

LASER EXHAUST BLOWER

$265.00 – $400.00 -

∅20mm CO2 LASER LENS

$150.00 -

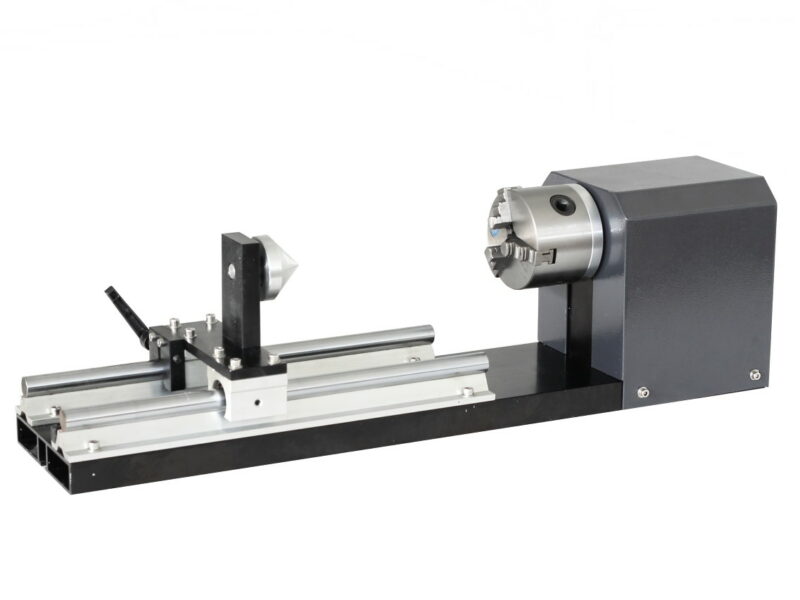

CO2 LASER ROTARY ATTACHMENT

$750.00

Reviews

There are no reviews yet.